28 Jan Hollow Core Fiber: From Latency Curiosity to Real-World Deployment

In recent years, hollow core fiber (HCF) has moved from academic curiosity to serious industry discussion, driven largely by the growing demand for ultra-low latency networks.

The most visible early applications have been in high-frequency trading (HFT), where microseconds translate directly into financial advantage. This demand has led to the first real-world deployments of hollow core fiber in European networks, where latency-sensitive routes have justified the adoption of a fundamentally new fiber technology. Momentum behind hollow core fiber accelerated further when Microsoft acquired Luminosity, a leading innovator in hollow core fiber design and manufacturing.

This acquisition was widely viewed as a strong signal that hyperscale cloud providers see hollow core fiber as strategically important. Notably, Microsoft’s decision to move hollow core fiber manufacturing to Corning’s Wilmington, North Carolina fiber plant suggests confidence not only in the technology’s maturity, but also in the potential for scalable, widespread deployment in the near future.

But what exactly is hollow core fiber, and why does it matter?

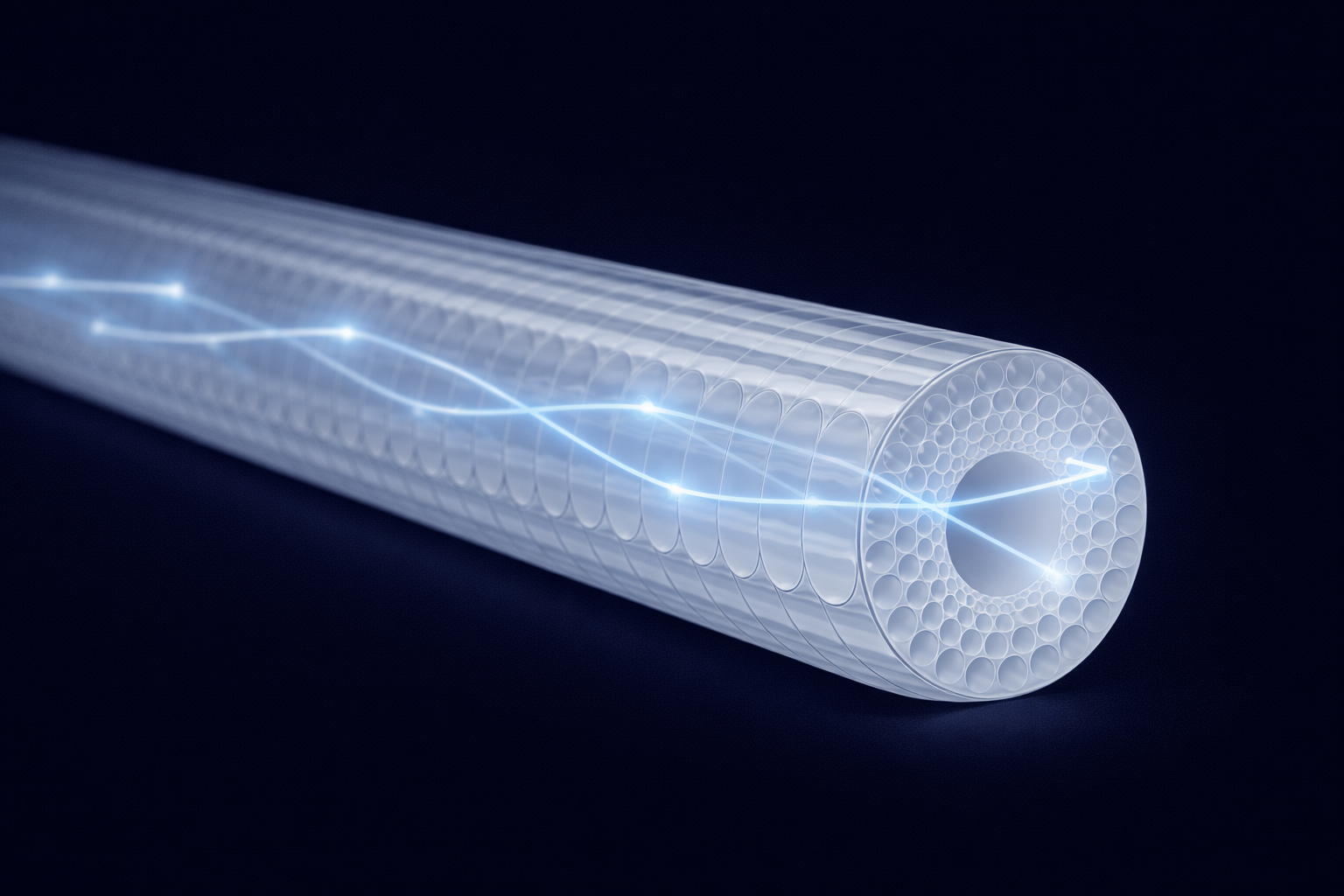

Unlike conventional optical fibers, which guide light through a solid silica glass core, hollow core fiber—as the name implies—guides light through an air-filled core. In standard single-mode fiber, light propagates at roughly 200,000 km/s, about two-thirds the speed of light in vacuum, due to the refractive index of glass. In hollow core fiber, however, light travels predominantly through air, allowing propagation speeds closer to 300,000 km/s. The result is a substantial reduction in latency, making hollow core fiber uniquely attractive for applications where every nanosecond counts.

How Light Propagation Differs in Hollow Core Fiber

The way light is guided in modern hollow core fiber differs fundamentally from conventional fiber. Traditional fibers rely on total internal reflection, achieved by surrounding a higher-index core with lower-index cladding. Hollow core fiber cannot use this mechanism because air has a lower refractive index than glass. Instead, modern hollow core designs—typically based on anti-resonant reflecting optical waveguide (ARROW) principles—use carefully engineered microstructured glass surrounding the air core. These structures act as wavelength-selective mirrors, reflecting light back into the hollow core and preventing leakage into the cladding. As a result, most of the optical power remains in air rather than glass, dramatically reducing interaction with the material.

This reduced light–glass interaction brings additional benefits beyond latency. Nonlinear effects, particularly the Kerr effect that limits performance in high-capacity coherent systems, are strongly suppressed. Chromatic dispersion and scattering losses are also reduced, opening the door to higher launch powers and cleaner signal transmission.

Remaining Challenges

Despite its promise, hollow core fiber still faces challenges before it can see mass adoption. Attenuation, while improving rapidly, remains higher than the very best conventional fibers over long distances. Hollow core fibers are also more sensitive to bending and splicing and connectorization require specialized techniques to minimize coupling losses. Manufacturing complexity and cost must continue to improve to support deployment beyond niche, latency-critical routes.

To learn more about optical networking, explore our optical network training page.

Sorry, the comment form is closed at this time.